eRun

eRun is industrial automation software developed by the Windows-based operating system with its own technology.

Even if you do not have expert computer programming knowledge, you can connect the user’s screen or the automation device (PLC, sensor, robot, various device controller, etc.) and remotely monitor or control the operation status, danger status, measurement value, set value, etc. of each device through the simple connection of the PC.

With open system structure, post maintenance and maintenance are done smoothly after the system is built, and it can be said that the management cost reduction is excellent.

This can be possible monitoring and auto control system!

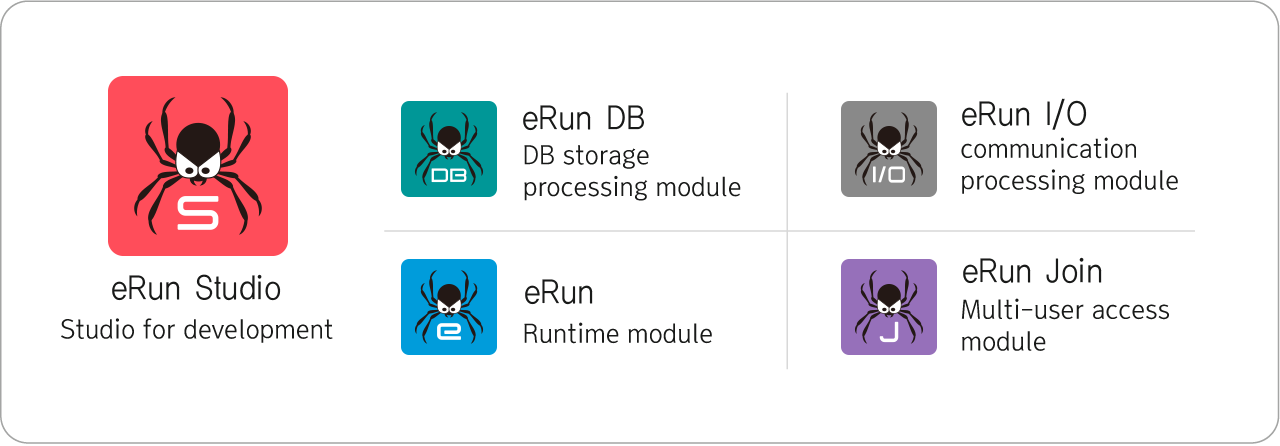

Relationship diagram of eRun

Relationship diagram of

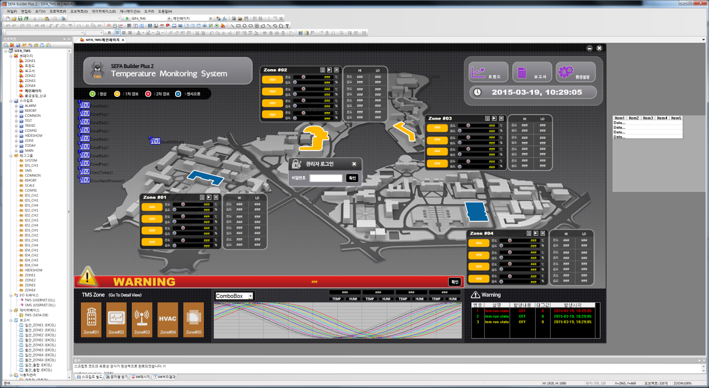

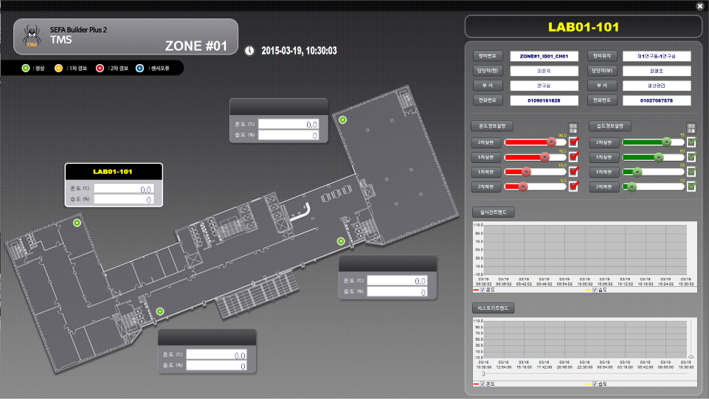

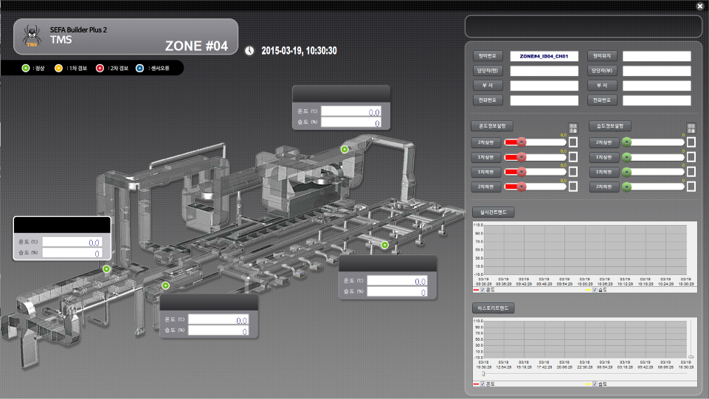

SEFA Builder Plus Ⅱ

References

%

Company

%

Association

%

Education

%

Etc.

- Temperature and humidity monitoring

- Flow monitoring

- CCTV and access control

- HVPE

- Rainfall / Precipitation / Snowfall Monitoring

- Structural Safety Diagnosis

- Production informatization

- Constant processing

- Sewage treatment

- Power control

- Lighting control

- Process Control / Monitoring

- Air conditioning system

- Control system

- power plant

- Chemical factory

- Water level monitoring

- Home Automation

- Remote monitoring system

- Automation of experimental facilities

- Refrigeration / Refrigeration Equipment

- Production control system

- Greenhouse control

- Crime prevention equipment

- Solar power generation

- SCADA

- Parking Facility

- Environment TMS

- Factory Automation

- Distributed control

- steel

- cement

- Storage monitoring

- Water treatment

- Water quality measurement system

- Transmission system

- Logistics Automation

- Building Automation

- Gas monitoring

- Boiler equipment

- Incinerator

- Other automatic controls

REFERENCE

Temperature and Humidity Monitoring System

As a system for monitoring and controlling the temperature and humidity of the industrial site, Check the temperature and humidity conditions of each area using wired / wireless communication (wired [RS232, 485, etc.] and wireless [ZigBee etc.]

Temperature and humidity can be adjusted automatically / manually, and data collection can be managed.

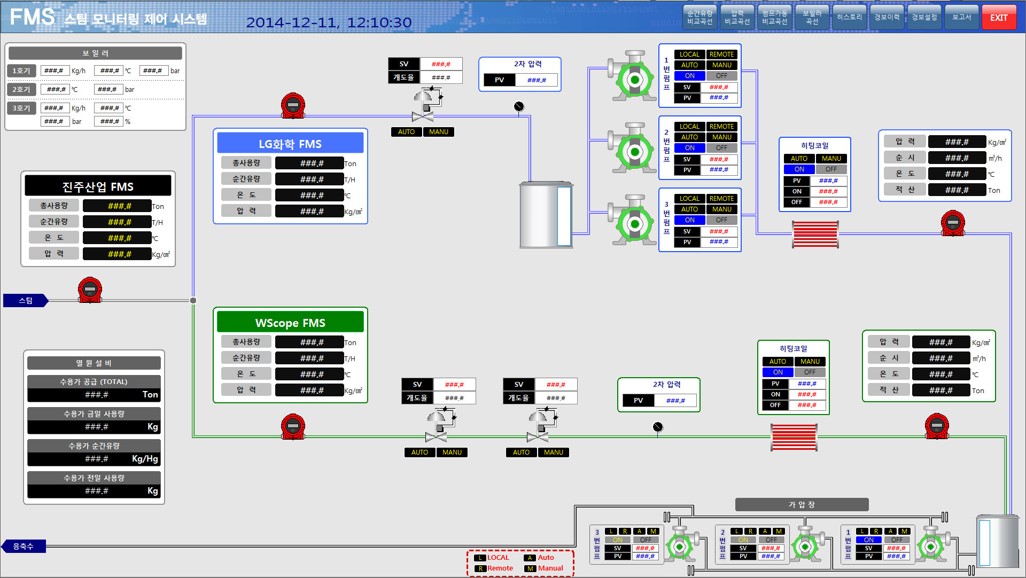

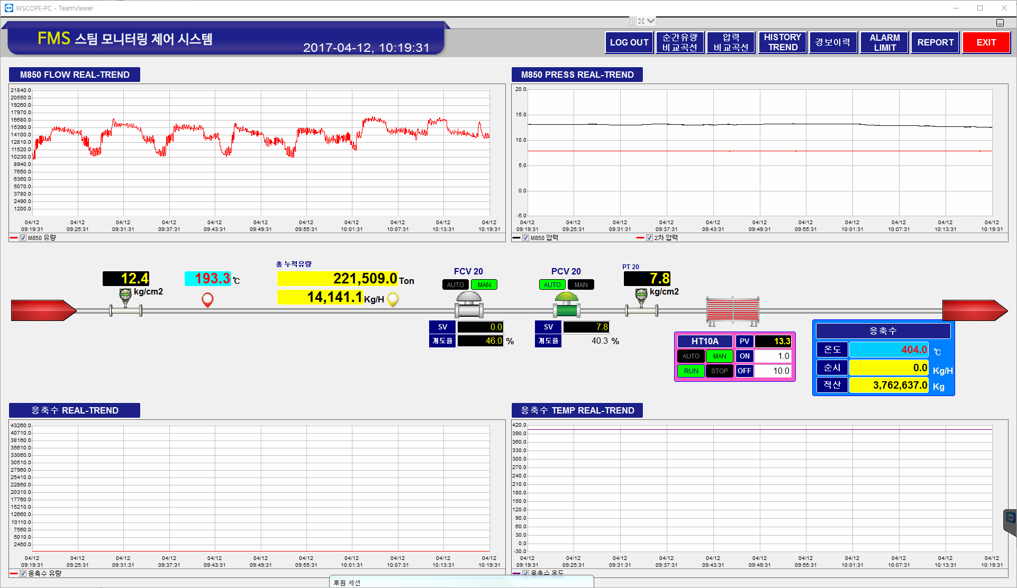

Remote flow control monitoring system

As a system for remote monitoring and control of flow, (Wired [RS232, 485, TCP / IP, etc.]) of the supply source and the destination, The flow rate can be adjusted automatically / manually, and the data can be collected and managed.

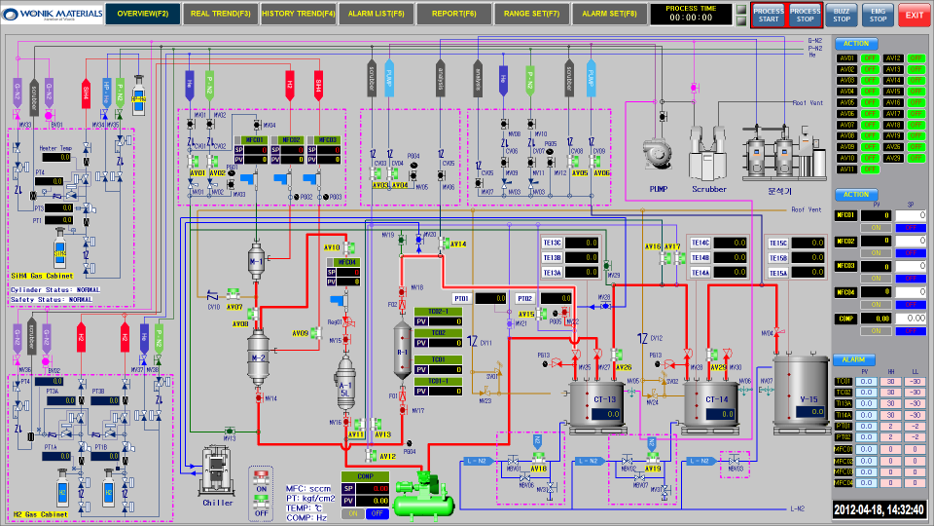

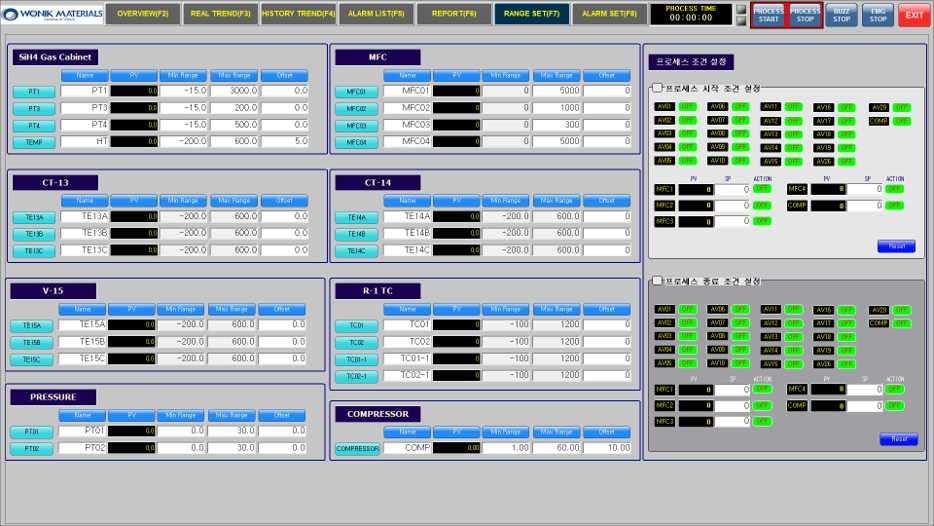

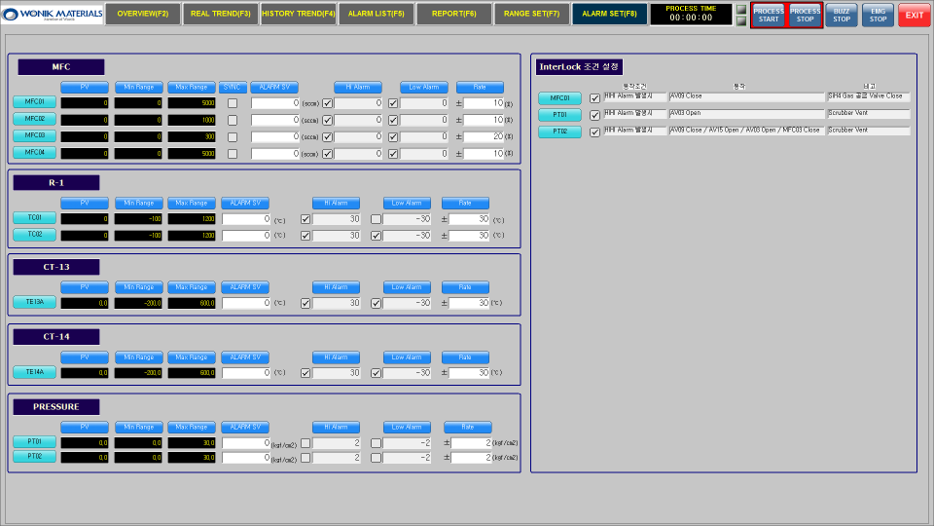

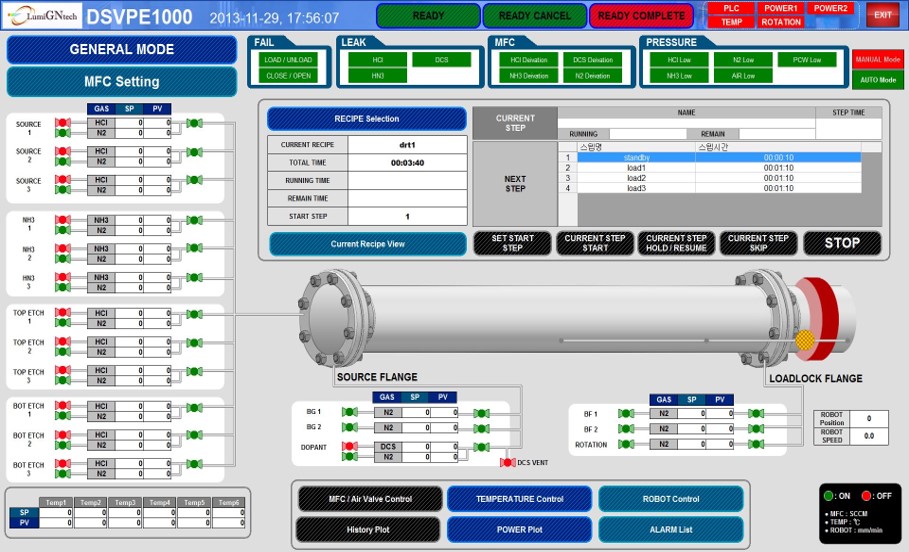

Factory Automation (FA) System

As a system for factory automation, Wired communication (wired [RS232, 485, TCP / IP, etc.]) between each device and SEFA Builder Check the status of each device, and control and monitor all devices and systems.

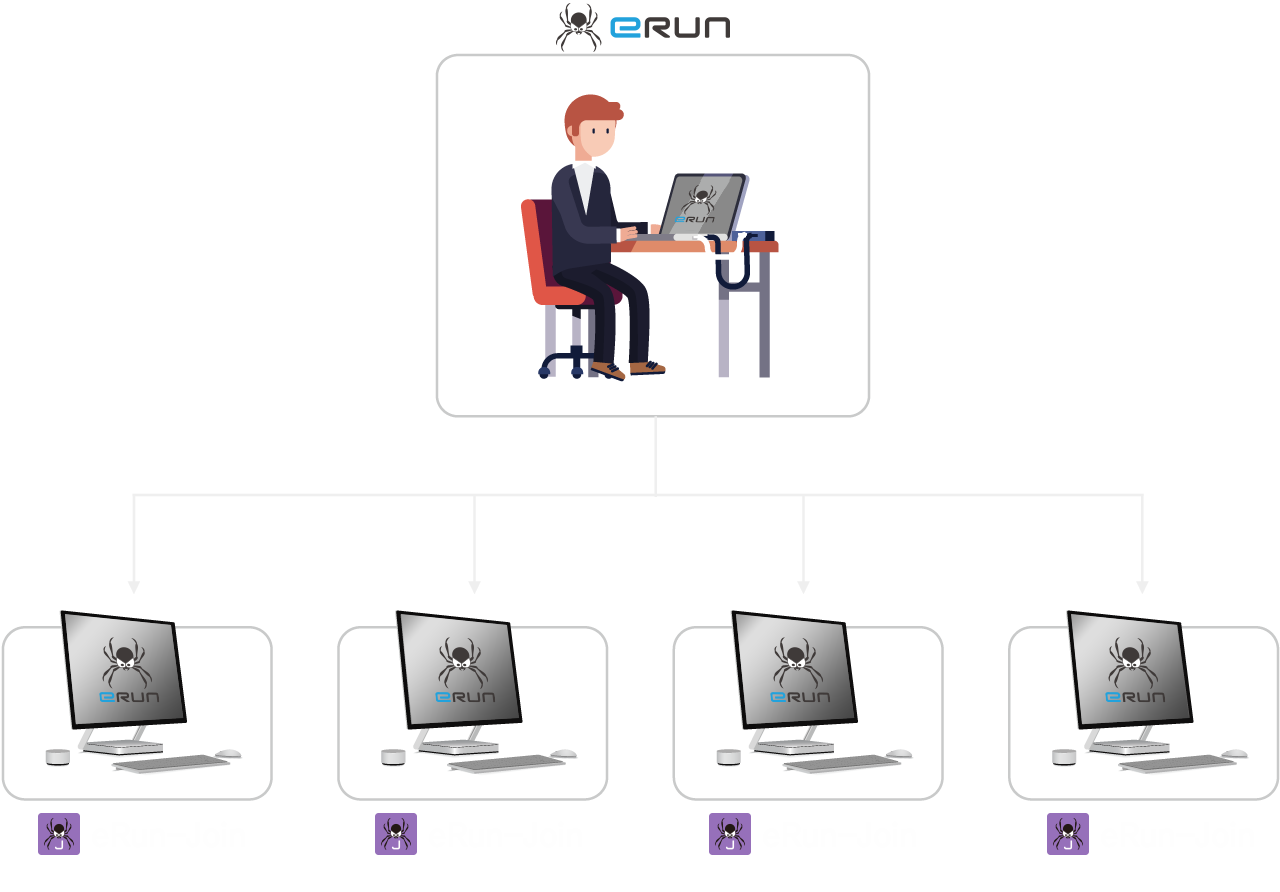

Multi-user access system

Multi-user

access system

SEFA Builder + II solution multi-user access system By utilizing this, one Server can be connected to a SCADA / HMI system. It is accessed through the multi-user connection program “SF-Join” Control / monitor the same screen as the server on the administrator PC Enabling system

Server Page

Tool : Runtime Engine SEFA Runner

Monitors the status of all the devices in the factory and controls each device automatically / manually

Administrator PC Multiple Access

Tool: Multi-user access SF-Join

Monitor the status of all devices on the administrator PC and control each device.

![]()

eRun Download

SEFA Builder Plus Ⅱ

Download